Industrie-Nachrichten

What Factors Should Be Considered When Choosing An Industrial Macro Lens?

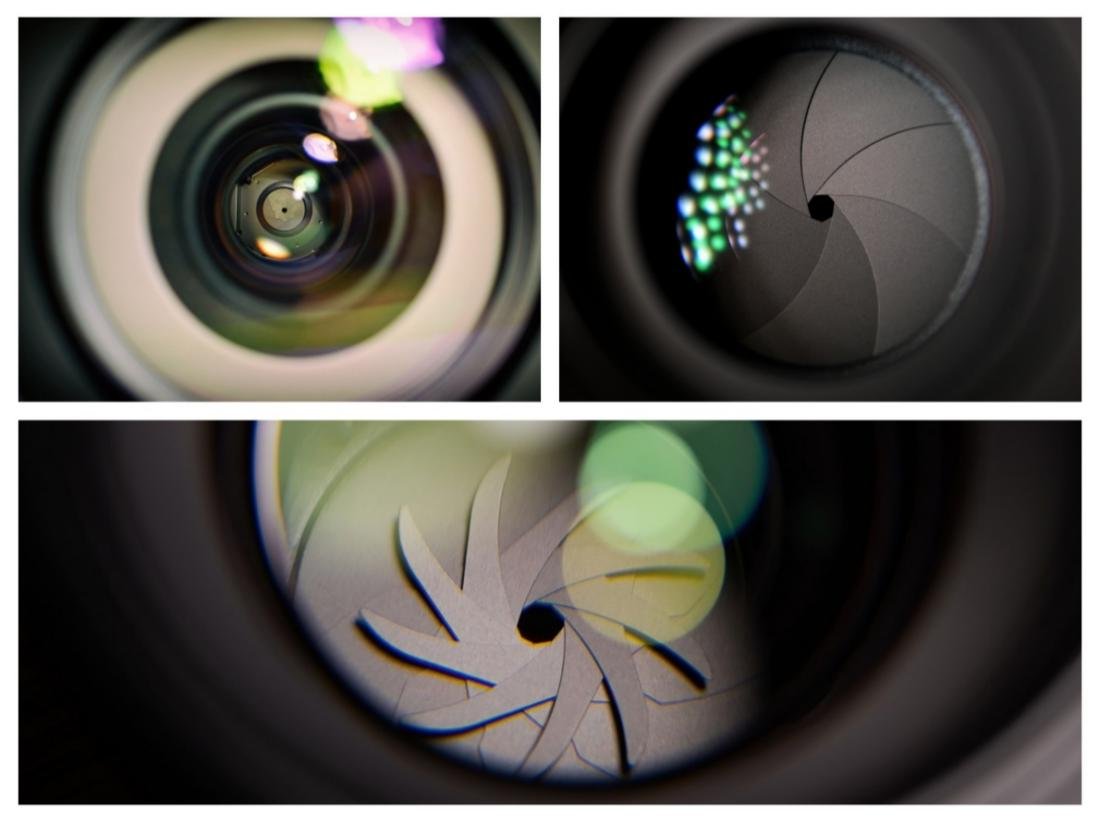

Industrial macro lenses are primarily used in industrial applications such as inspecting electronic components and mechanical parts. The objects being inspected are typically small and require close-up photography. When choosing an industrial macro lens, several factors need to be considered to ensure it meets specific application needs and performance requirements.

1.Focal length range

Focal length determines the shooting range and magnification of a lens. Industrial macro lenses typically have focal lengths between 40mm and 100mm. Shorter focal lengths provide a larger field of view but lower magnification, suitable for inspecting larger surface areas or observing overall structures; longer focal length lenses offer higher magnification, allowing for the observation of fine details of objects, but with a smaller field of view, often used for inspecting small parts or applications requiring high precision.

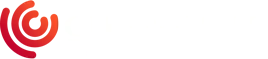

2.Aperture size

The aperture affects both the brightness and depth of field of an image. Lenses with a large aperture can absorb more light, making them suitable for shooting in low-light conditions, and can also achieve a shallow depth of field to highlight the subject; lenses with a small aperture have a greater depth of field, allowing objects at different distances within a certain range to appear relatively sharp, making them suitable for scenes where objects at varying distances need to be in focus simultaneously.

3.Vergrößerung

The appropriate magnification needs to be selected based on the size of the object being inspected and the required level of detail. A normal 1:1 magnification ratio is sufficient for most macro photography needs.

Generally, for surface inspection of ordinary industrial parts, a magnification of 0.5-2 times may be sufficient; however, for scenarios requiring higher precision observation of minute details, such as observing tiny objects like integrated circuit chips, a magnification of 5-10 times or even higher may be needed to clearly observe their internal structure and minute defects.

4.Optical performance and distortion control

The optical performance of a lens mainly includes indicators such as distortion, aberration, and chromatic aberration. Industrial inspection requires high image geometric accuracy, and lens distortion needs to be less than 0.05% to ensure measurement accuracy. Low distortion lenses can ensure that the shape of the captured object is not distorted, which is crucial for industrial applications requiring precise dimensional measurement and shape inspection.

Lenses with low aberration and chromatic aberration can provide clearer images with higher color fidelity, which helps in accurately identifying object features and defects. For example, when inspecting color printed materials, good color reproduction and low chromatic aberration performance can accurately determine the accuracy of printed colors and whether there are registration errors.

5.Working distance

The working distance refers to the distance from the front of the lens to the surface of the object being inspected. It should be selected based on the spatial constraints between the inspection equipment and the object, as well as the convenience of operation.

For applications requiring inspection in confined spaces, such as inspecting components inside equipment, a lens with a shorter working distance should be chosen. Conversely, for objects that are difficult to approach or situations where the lens needs to be protected from heat, dust, or other environmental factors, a lens with a longer working distance should be selected.

6.Auflösung

The lens resolution needs to match the camera sensor to ensure image clarity. High-resolution lenses provide sharper, more detailed images, suitable for precision measurement or defect detection, helping to detect smaller defects and features.

When selecting an industrial macro lens, choose one with a resolution that meets the required detection accuracy. For example, when detecting tiny cracks in precision mechanical parts, a lens with sub-micron resolution is needed to accurately identify the location and size of the cracks.

7.Mount type

Common mounts for industrial lenses are C-mount or CS-mount, which need to be compatible with the industrial camera. Different camera brands and models may support different mount types, so when choosing a lens, ensure that its mount is compatible with the camera being used to guarantee proper installation and operation.

8.Environmental adaptability

Industrial production environments are typically complex and diverse, potentially involving high temperatures, low temperatures, humidity, dust, and vibration. Therefore, it is necessary to select industrial macro lenses with appropriate environmental adaptability.

For example, when working in high-temperature environments, the lens should have good heat dissipation and high-temperature resistance, and its operating temperature range must cover the application environment to ensure stability; when used in humid or dusty environments, the lens needs to be sealed and have dustproof and waterproof designs to prevent moisture or dust from entering the lens and affecting image quality.

In summary, when choosing an industrial macro lens, it is necessary to consider various factors such as focal length, aperture, magnification, working distance, and resolution to ensure that the selected lens meets the specific application requirements.